Concrete Septic Tanks Are Probably Your Best Option

1000 Gallon Concrete Septic Tank

If you happen to be in the market for a new septic system, or simply looking to replace an old septic tank, well you’ve come to the right place!

We recently took a look at various septic systems options available for your home, and thought it would also be a good idea analyze the different types of septic tanks currently on the market.

The three most popular types of septic tanks readily available for installation are:

Concrete

Fiberglass

Plastic/Polyethylene

“If built properly and maintained on a regular basis though, most concrete septic tanks can last up to 40 years.”

No matter your choice, keep in mind that in order to keep a home’s septic system healthy and functioning properly, it should be cleaned, checked for leaks, and professional serviced every 3-6 months.

Septic Tank Sizes

There are many different charts and recommendations for septic tank sizes by waste flow, house size, square footage, number of bedrooms, number of bathrooms, and even a few other qualifiers. The septic tank size required in a specific area will also depend on both state and local regulations.

Septic tanks come in varying sizes, and you can get tanks that are smaller than 1000 gallon, but we recommend that you stick with 1000 square feet as the minimum size tank. Several states now require 1000 gallon tanks as the minimum size requirement.

If you’re planning to install a new septic tank or septic system, please be sure to consult a licensed professional prior to purchasing or installing any equipment. Every state and local town has strict rules regarding different product sizing and installation methodology.

“Several states now require 1000 gallon tanks as the minimum size requirement.”

Concrete Septic Tanks

Concrete septic tanks are currently the most popular type of septic tank on the market. The concrete septic tank’s popularity is due to its strength, weight, and durability. More specifically as to durability, if constructed properly, concrete septic tanks have a lower likelihood of breaking, cracking, or floating.

Check out these 6 septic systems available for your home.

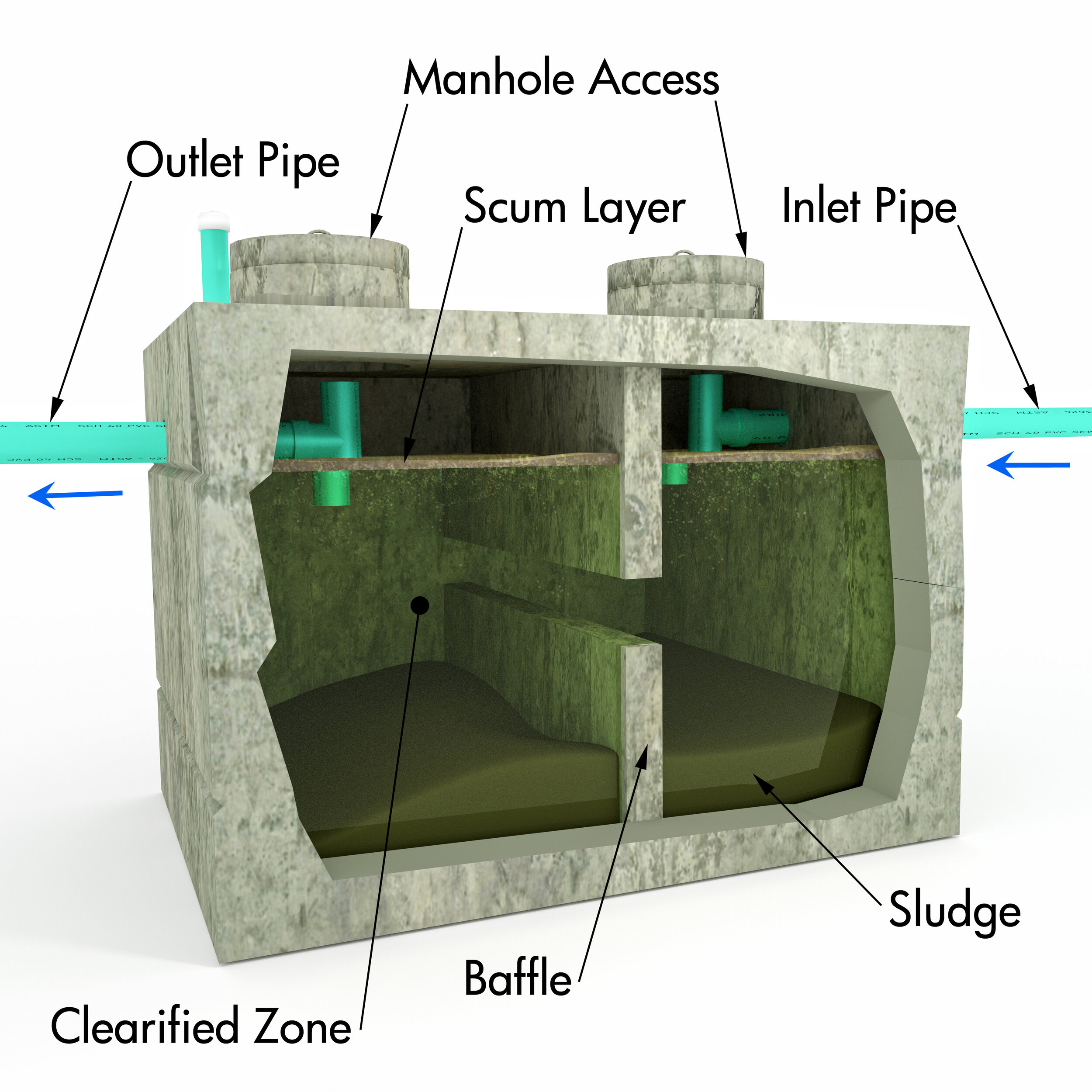

Two Compartment Tanks vs. One Compartment Tanks

Today, most concrete septic tanks are sold with a two compartment design vs. the older style one compartment tank. The two compartment tanks tend to do a better job of filtering and separating, therefore they are recommended by septic experts over a one compartment tank.

Regardless of the number of compartments, all compartments are designed with access for cleaning and pumping.

“The most common size for domestic use is a 1000 gallon septic tank since it easily accommodates most 0-3 bedroom homes.”

Heavy Duty Options

Many tanks also come in a “heavy duty” form, which typically includes a reinforced top. Opting for the heavy duty version can be a good move in the event an automobile, farm equipment, or another heavy machinery drives over the tank area.

Installation Requirements

All concrete septic tanks require professional installation due to their size and weight.

These tanks are made of the heaviest materials available, and although they are rugged, they require large, heavy equipment to install. If your concrete septic tank’s proposed or current location doesn’t provide access for heavy machinery, you may want to consider a fiberglass or plastic (polyethylene) tank.

Since most concrete tanks are made precast, they all differ in size, weight, and dimension. But keep in mind that all of these specifications are approximate and subject to state and local code.

Lifespan and Durability

The long-term performance of the concrete septic tank will depend on how it was manufactured. High quality concrete, proper water sealing, and the addition of structural steel products like mesh and rebar will add support, strength, and structural integrity.

Be aware that concrete septic tanks can crack under extremely cold conditions, and are more prone to leaking than their plastic and fiberglass counterparts.

If built properly and maintained on a regular basis, most concrete septic tanks can last up to 40 years.

Hole dug for 1000 Gallon Concrete Septic Tank

1000 Gallon Concrete Septic Tank

Overview: The most common size for domestic use is a 1000 gallon septic tank as it easily accommodates most 0-3 bedroom homes.

Size & Weight: All concrete tank sizes vary. Some of the most popular 1000 gallon concrete precast tanks are around 5’ 1” X 8’ 2” X 5’ 8” and weigh almost 9,000 lbs. Here are examples from Jensen Precast in various cities across the US.

Excavation Depth: Around 9 1/2 feet in depth which varies by distributor, state and local statute

1250 Gallon Concrete Septic Tank

Overview: A 1250 tank is a common choice for mid-size homes with 3-4 bedrooms.

Size and Weight: All concrete tank sizes vary. Some of the most popular 1250 gallon concrete precast tanks are around 5’ 9” x 8’ 6” x 5’ 8”.

A 1250 gallon concrete tank weighs an average of 11,000 lbs, although that can vary by distributor.

Excavation Depth: Around 11 1/2 feet in depth which varies by distributor, state and local statute

Extras: Many of these larger tank sizes are so heavy that rebar and wire mesh become a necessary component within the walls and in between layers for added strength, stability, and longevity.

1500 Gallon Concrete Septic Tank

Overview: The 1500 gallon tank is the most common choice for large homes with 5+ bedrooms.

Size and Weight: All concrete tank sizes vary. Some of the most popular 1500 gallon concrete precast tanks are around 6’ x 10’ 9” x 5’ 5”. Many 1500 gallon concrete tanks weighs an average of 12,000 lbs.

Excavation Depth: Around 12 feet in depth which varies by distributor, state and local statute

Septic Tank Baffles

Input and output baffles help to filter the solid waste materials, oils and scum from the effluent.

Inlet Baffles

An inlet baffle is installed on the inlet portion of the septic tank closest to where the sewer tank connects from the housing structure to the tank. The inlet baffle is crucial to the health and success of the entire septic system because it prevents the flow of scum and oils from clogging the inlet pipe.

The inlet baffle is a bottle neck specifically installed to:

Slow the effluent from entering the septic tank: in-flow of effluent at a high speed can disturb the breakdown process by inadvertently mixing the settled solid waste in with the oils, scum and effluent

Prevent sewer gases from entering the sewer line. These gasses can permeate back in to a home or building causing a noxious smell.

Outlet Baffles

Every septic tank should have an outlet baffle attached to the outlet pipe.

Similar to the inlet baffle, but in reverse, the outlet baffle also acts as a bottle neck designed to:

Keeping scum, oils, and solid waste in the septic tank

Preventing the expulsion of waste materials other than effluent in to the outlet pipe and drain field/leach field.

All expelled effluent from the septic tank must be free of solid waste. Otherwise, the solids and oils will contaminate the drain field/ leach field causing backups and pollutants to enter the environment.

If you’re unsure if your baffles are installed properly or might be in need of repair, be sure to check with a certified septic professional.

Fiberglass and Plastic (Polyethylene) Septic Tanks

Fiberglass and plastic (polyethelyene) septic tanks are also a good choice, especially under specific conditions in your area.

Heavy duty plastic (polyethylene) septic tank

Mobility

Both fiberglass and polyethylene septic tanks can easily be moved by a labor crew, whereas concrete septic tanks typically require a truck equipped with a crane and boom. As as result, fiberglass and plastic tanks are often used in areas inaccessible to concrete septic tank delivery trucks.

Most fiberglass and plastic septic tanks weigh in around 300+ lbs vs. concrete versions that easily weigh 20-30 times as much.

Cost Effectiveness

At a fraction of the cost fiberglass and plastic (polyethylene) are great options if you’re looking for a less expensive alternative to concrete.

Most fiberglass and plastic septic tanks are thousands of dollars less than concrete.

Durability

Both plastic and fiberglass septic tanks are less likely to crack compared to a concrete septic tank. And since fiberglass and plastic are nonporous materials, there’s usually no issue with tree or bush roots growing in to the tank and causing leaks through root damage.

That said, care must be taken during installation as heavy machinery can easily damage a tank due to it’s thinner profile and lighter material makeup. Like concrete a tank, fiberglass/plastic tanks can also be damaged with too much weight placed on the surface above.

A septic professional will know to properly mark the ground above to avoid driving near the surface.

Although plastic and fiberglass tanks are durable, in certain conditions they can still spring a leak. So it’s best to consult a septic installation professional before committing to a specific material.

Lot size, tank location, ground water levels, and weather can all play in to the decision.

Float

The benefits of plastic and fiberglass can also be problematic. Yes, the lightweight nature of both materials is ideal for installation, but that lightweight nature results in high buoyancy.

It can happen that in a storm, a plastic or fiberglass tank can dislodge from their couplings, which can cause significant damage to the septic system and homeowners property, costing thousands of dollars to remedy.

An easy fix is to pour a concrete slab to aid in weighing down the tank. There is some irony though in pouring a concrete bed and tethering it to a fiberglass/plastic septic tank for stability.

If you live in an area with high ground water, seek out a professional to be sure that the higher water table won’t damage your fiberglass/plastic tank.